M-Bus Converters for BMS and Automation Systems

M-Bus Converters

This category includes converters with an M-Bus interface. M-Bus is a standard used for reading various types of consumption meters, such as gas meters, water meters, electricity meters, heat meters, and others. The standard consists of a communication protocol and an electrical interface, which is why an additional converter is required to translate the data into an interface/protocol that is understandable to the data collection controller.

M-Bus converters bridge the gap between the world of meters and energy management and building automation systems. Their main task is to convert the signal from the M-Bus bus, which is optimized for meter reading, into standard communication protocols such as Modbus TCP, BACnet, or PROFINET. Thanks to this, data from meters can be easily integrated with BMS (Building Management Systems), SCADA, and other monitoring solutions. This is a crucial step in building smart buildings and factories where energy efficiency and accurate consumption billing are a priority.

What You'll Find Here

We have prepared various types of M-Bus converters for you, depending on the standard you want to use to read the meters. Our offer includes M-Bus converters for: BACnet Ethernet, BACnet MS/TP, DeviceNet, Ethernet, KNX, Modbus RTU, Modbus TCP, PROFIBUS, PROFINET, SNMP, RS-232, RS-485, and USB.

The versatility of our offer allows you to adapt the solution to any infrastructure. M-Bus converters to Modbus TCP and Modbus RTU are ideal for integration with popular PLC controllers. M-Bus to BACnet/IP gateways are standard in advanced BMS systems, enabling central management of utility consumption. Additionally, we offer converters for industrial protocols such as PROFIBUS and PROFINET, which are indispensable for monitoring utility consumption in large manufacturing plants.

Applications and Benefits of M-Bus Converters

Thanks to M-Bus converters, data from meters can be read automatically and sent to a central system, which eliminates the need for manual readings. This is especially useful in large commercial buildings, residential complexes, and industrial facilities. An M-Bus to Modbus TCP converter allows for real-time monitoring of water, gas, or energy consumption, which enables quick detection of leaks or irregularities. This data can then be used to create reports, analyze trends, and optimize consumption.

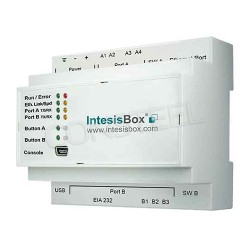

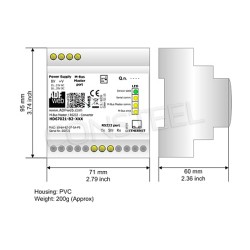

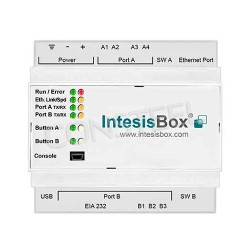

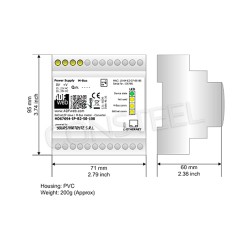

Our devices are also equipped with advanced features, such as galvanic isolation, which protects sensitive meters and controllers from damage caused by power surges in the network. A solid construction, DIN rail mounting, and a wide operating temperature range from -40°C to 85°C guarantee reliability in the most demanding conditions.

Smart Energy Management

In an era of rising energy prices and increased ecological awareness, M-Bus converters are an essential tool for building smart energy management networks. They enable the implementation of AMR (Automatic Meter Reading) systems, which automate the process of reading, monitoring, and billing consumption. Whether you need to read a dozen meters in a small building or hundreds in a large industrial complex, our converters will ensure stable and efficient communication. The choice of the right converter depends on the number of meters you want to connect (the number of slave units) and the master protocol with which it is to cooperate.

What Problems Do M-Bus Converters Solve?

M-Bus converters are more than just signal conversion devices. They solve a number of key problems faced by building managers, engineers, and network administrators. The first and most obvious is the problem of protocol incompatibility. Utility meters (water, gas, electricity, heat) often communicate exclusively using the M-Bus protocol, which is not understood by most advanced automation systems (e.g., Modbus, BACnet). A converter eliminates this barrier by translating the data into a language that is understandable to the master system.

Another significant problem is manual meter reading. It is not only time-consuming but also prone to human error. In large facilities where meters are located in many hard-to-reach places, automated reading with an M-Bus converter significantly saves time and resources and provides greater data accuracy. This allows for continuous monitoring of consumption, which is invaluable in energy management.

In industrial and commercial environments, there are often electromagnetic interferences and power surges in the power grid. Meters and controllers are sensitive devices that can be damaged. Our M-Bus converters, thanks to built-in galvanic isolation, effectively protect connected devices from such problems, increasing the reliability and safety of the entire installation. Additionally, the wide operating temperature range ensures that the converters operate stably in extreme conditions, from frost to heat.

Last but not least, the problem is the lack of data centralization. Without converters, data from meters is scattered, which makes it difficult to analyze and generate reports. Thanks to a converter, all data is collected at one point and made available to master systems, which enables effective utility management, predictive maintenance, and cost optimization.

For your convenience, we have divided our M-Bus converters according to the technology they support. Choose the one that interests you and see the available converters. You will find them here:

-120x120w.png)

-120x120w.png)