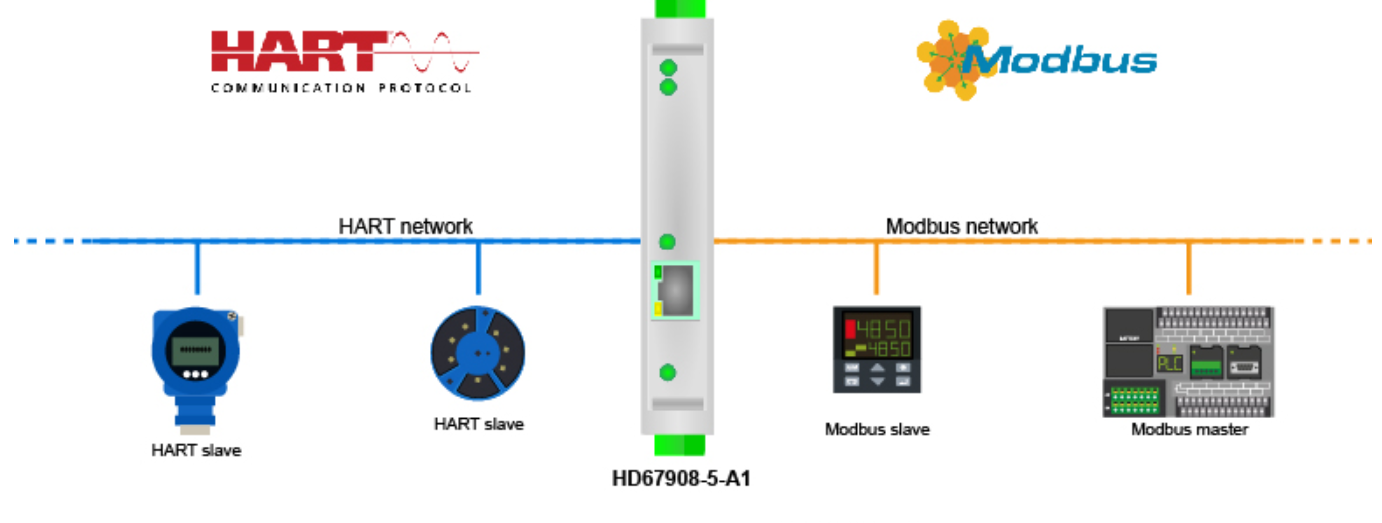

HD67908-5-A1 Modbus RTU Slave to HART Master – converter for sensors integration

HD67908-5-A1 is Industrial Modbus slave to HART master converter, housing type A (slim), DIN rail mount.

- Stock: 3-4 days

- Brand: ADF Web

- Model: HD67908-5-A1

Full design package: User manual, CE declaration, CAD, PDF, certificates and test reports

If you're preparing technical documentation or an installation design, you can receive a complete set of design materials for this model. This is a quick way to gather the required documents for audits, acceptance, or project documentation.

- Device User Manual

- CE Declaration of Conformity (EU Declaration of Conformity)

- Mechanical Drawings – CAD (STEP/DWG) or high-quality PDF

- Additional Certificates and Test Reports (if available for the model)

Industrial Modbus slave to HART master converter, housing type A (slim), DIN rail mount.

HD67908-A1 it allows you to monitor HART devices (like Sensors, etc..) with a Modbus net (like PLC, Supervisory System etc..).

The HD67908-5-A1 converter is designed for industrial environments where integration between Modbus RTU and HART field devices is essential. By acting as a Modbus RTU slave and HART master, it enables a supervisory system, PLC, or SCADA to access valuable diagnostic and process data from HART-enabled transmitters, sensors, and actuators. This is particularly useful in process industries such as oil & gas, chemical plants, water treatment, energy and HVAC, where HART devices are widely deployed.

The device not only provides digital HART communication but also supports a 4–20 mA analog input, which is a standard in industrial automation. This dual capability makes the converter a flexible solution for both modern digital networks and legacy analog systems. Operators can monitor process values through analog signals while accessing extended diagnostics and configuration data via the HART channel. This feature improves predictive maintenance strategies, reduces downtime and helps ensure higher system reliability.

Thanks to its compact slim housing (type A) and DIN rail mounting, the HD67908 is easy to install in crowded control panels. The rugged design allows reliable operation across a wide temperature range from -40°C to +85°C, making it suitable for both indoor and outdoor applications. The device is lightweight (200 g approx.) yet robust enough for harsh industrial conditions. It can be powered flexibly from 8–19 VAC or 8–35 VDC, giving integrators multiple installation options.

The free SW67908 configuration software provides a user-friendly interface for defining Modbus parameters, mapping HART variables, and updating device settings. Engineers can quickly configure baud rates, address mapping, and select which HART values should be exposed as Modbus registers. This significantly reduces commissioning time and simplifies integration with SCADA or PLC systems.

In typical applications, the HD67908 can be used to connect pressure transmitters, flow meters, temperature sensors, and valve positioners with supervisory Modbus RTU systems. It ensures that field operators can access both the primary process variable (PV) and additional secondary diagnostics (SV, TV, QV), enhancing control accuracy and system monitoring. Such functionality is critical in industries where equipment uptime and data integrity are paramount.

Specifications:

- Ports: 1x RS485; 1x HART

- Modbus protocol: Modbus RTU slave

- HART protocol: HART FSK Master + 4..20mA Analog Input

- Data rates Modbus: Up to 115200 bps

- Data rates HART: 1200 bps

- Modbus connector: 3way 5mm terminal block

- HART connector: 2way 5mm terminal block

- Power supply connector: 2way 5mm terminal block

- Power supply: 8...19 VAC; 8...35 VDC

- Operating temperature: -40° to +85° (-40°F to +185°F)

- Dimensions: 120 mm x 23 mm x 107 mm (DxWxH)

- Weight: 200 g approx

- Mechanical fixing: DIN Rail mount

- Software: SW67908

- ORDER CODE: HD67908-5-A1

Configurator – Software SW67908 FREE DOWNLOAD

Manufacturer's warranty: 24 months

The HD67908-5-A1 is widely recognized as a bridge between traditional HART field devices and Modbus-based automation systems. Its ability to combine digital and analog channels makes it an attractive solution for modernizing plants without replacing existing instruments. By enabling centralized access to diagnostic data, it enhances asset management and supports Industry 4.0 strategies.

For further details or technical support, please visit our contact page.

| General technical parameters | |

| Protocol support | Modbus, HART |

| Industrial grade | |

| Operating temperature | -40°C to 85°C |

| Input voltage | 8~24VAC, 12~35VDC |

| Manufacturer's warranty | 24 months |

| Mount | DIN rail |