Modbus RTU to BACnet IP – industrial gateways for BMS and automation

Industrial Modbus RTU to BACnet IP converters

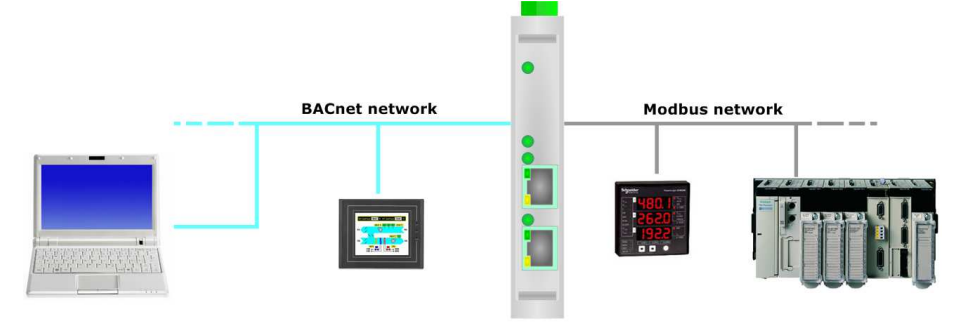

A Modbus RTU to BACnet IP converter (gateway) enables seamless integration between Modbus devices and BACnet-based building management systems (BMS). It bridges slave/server and master/client devices across both protocols, allowing, for example, a PLC, HMI, or supervisory BMS to communicate directly with HVAC units, sensors, meters, and other Modbus field devices. These converters are widely used in modern automation projects, where interoperability and scalability are critical.

Modbus RTU is a serial protocol, typically implemented over RS-485, known for its simplicity, reliability, and low cost. It is an excellent solution for short-distance communication with multiple field devices in industrial environments. On the other hand, BACnet IP is an Ethernet-based protocol that provides greater scalability, flexibility, and advanced communication capabilities across large BMS networks. A Modbus RTU to BACnet IP gateway combines the strengths of both protocols, enabling real-time data exchange between local field devices and supervisory systems operating on TCP/IP.

Key benefits of Modbus RTU to BACnet IP gateways

Every Modbus RTU to BACnet IP gateway in our portfolio is designed for industrial-grade environments, offering robust performance and long-term reliability. Key features include DIN rail mounting for quick installation, resistance to electromagnetic interference, and a wide operating temperature range from -40°C to +85°C. This ensures consistent operation both in high-temperature control cabinets and in outdoor enclosures exposed to frost or humidity. Such versatility makes these devices an essential part of mission-critical automation projects where uninterrupted operation is required.

Connectivity is flexible thanks to the availability of RS-232, RS-485 screw terminals, and Ethernet RJ45 ports. Converters support both 12–35 VDC and 24 VAC power supplies, allowing for easy integration into diverse electrical environments. Depending on the model, gateways can operate in two major modes: Modbus slave – BACnet client (master), where Modbus is the subordinate network, or Modbus master – BACnet server (slave), where BACnet is the supervisory network. This flexibility makes them suitable for projects with varying architectures and system hierarchies.

Configuration and scalability

All our Modbus RTU to BACnet IP converters come with free configuration software that simplifies setup and mapping of registers. The software allows intuitive assignment of Modbus registers to BACnet objects and supports diagnostics and firmware upgrades. Depending on the device, up to 2000 BACnet objects can be mapped, or up to 3000 points when licensed extensions are used. This makes the gateways scalable from small single-building applications to large industrial or commercial complexes.

Certification and compliance

Selected Modbus RTU to BACnet IP gateways are BTL-certified (BACnet Testing Laboratories), ensuring full compliance with BACnet standards. They support B-ASC (Advanced Application Controller) and B-AAC profiles, guaranteeing interoperability with BACnet BMS platforms from leading manufacturers. This certification is especially important in projects where multi-vendor integration and system reliability are critical requirements.

Application areas

Practical use cases for Modbus RTU to BACnet IP converters include:

- Integration of Modbus-based energy meters into BACnet IP building management systems

- Connecting Modbus temperature and humidity sensors to BACnet supervisory controllers

- Centralized control of HVAC units, chillers, and VRF/VRV systems over BACnet IP

- Lighting automation and energy optimization through BACnet-based platforms

- Real-time monitoring of utility consumption across industrial plants or office complexes

These gateways ensure smooth data exchange and provide system integrators with the flexibility to design automation networks that are both scalable and vendor-independent. By bridging Modbus RTU devices with BACnet IP networks, they enable unified monitoring, control, and energy efficiency across entire facilities.

Choose the right Modbus RTU to BACnet IP converter

When selecting a Modbus RTU to BACnet IP converter, key factors include the number of supported points, type of available interfaces (RS-232, RS-485, Ethernet), supported communication modes, and certification. With a wide portfolio, our range covers everything from small-scale building automation systems to large industrial BMS installations. Review the detailed technical specifications of each model to select the most suitable gateway for your project requirements.