How to choose an IP68 keyboard for Panel PC and HMI when fast data entry matters

How to choose a keyboard for an HMI operator workstation and Panel PC

Panel PCs and HMI panels are the primary operator interface in manufacturing, logistics, and automation systems. A touchscreen works great for process visualization and simple control (e.g., start/stop, on/off, changing setpoints), but in practice many workstations also require fast and accurate data entry. That is exactly when an industrial keyboard becomes real support for the operator, improves ergonomics, and reduces the number of mistakes.

Do you need a keyboard for a Panel PC?

In most applications, a Panel PC is operated via touch. A keyboard is added as an accessory in scenarios where the operator must quickly type longer strings or frequently fill in text fields. The most common examples include:

- entering serial numbers, batch codes, and identification data,

- production reporting and logging completed operations,

- operator logins and entering service notes,

- filling out quality forms and text fields in the system,

- working with gloves, where typing on a touchscreen is inconvenient.

When a touchscreen is not enough

Even good touch panels have limitations in industrial environments. Problems most often occur when working with gloves, in humidity, when the screen is dirty, and when long strings must be entered quickly. In these conditions, a keyboard reduces handling time, improves accuracy, and helps the operator work smoothly without unnecessary interruptions.

Why an IP68 keyboard is essential in harsh working conditions

At many workstations, input devices are exposed to washing, moisture, splashes, dust, production debris, and cleaning agents. In such environments, standard keyboards quickly stop working or become difficult to keep clean. That is why IP68 keyboards are used in wet and hygienic areas, providing high sealing and the option for regular washing.

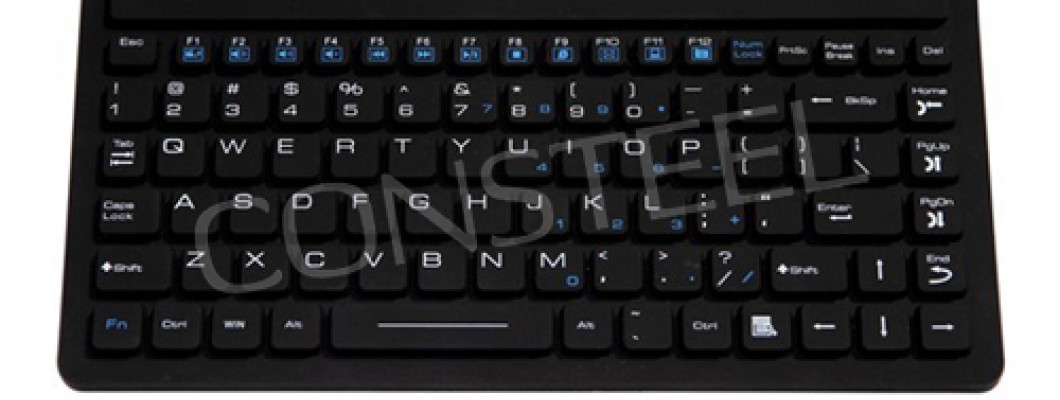

In practice, a very common choice is an IP68 silicone keyboard , because it has a smooth surface, no gaps, and is easy to clean and disinfect.

What types of keyboards are used at operator workstations

Keyboard selection depends on the working environment, usage intensity, and hygiene requirements. Most commonly used are:

- IP68 silicone keyboards – for wet, dusty environments and applications requiring regular cleaning.

- Stainless steel keyboards – for environments requiring high mechanical resistance and heavy-duty use: see stainless models .

- Industrial keyboards with touchpad or trackball – for workstations where it is convenient to combine data entry and pointing: industrial keyboards and touchpads .

- Compact models – when limited mounting space and quick access to keys matter.

IP68 silicone keyboard or stainless steel – which one to choose?

An IP68 silicone keyboard is a good choice where hygiene, washing, moisture, and easy cleaning are top priorities. A stainless steel keyboard works better in environments exposed to heavy use and a higher risk of mechanical damage. The final choice should be based on the actual workstation conditions and the operator’s working method.

What to consider when selecting a keyboard for a Panel PC

- Ingress protection rating (e.g., IP68) – when the workstation is washed or operates in moisture and dirt.

- Glove operation – important in production, warehouses, and hygienic zones.

- Resistance to chemicals – crucial for frequent disinfection and cleaning.

- USB / PS2 interface – fast integration with an industrial PC and HMI workstation.

- Ergonomics – comfortable data entry during shift work.

- Ease of cleaning – a smooth surface and no gaps help maintain hygiene.

In practice, a properly selected IP68 industrial keyboard reduces the risk of downtime caused by input-device failures and speeds up operator tasks that require data entry.

Example application scenarios

- Manufacturing and automation: reporting, entering batch data and serial numbers in dusty areas.

- Logistics and warehouses: WMS operation and entering product codes.

- Food industry: workstation washdown and hygiene requirements.

- Laboratories and healthcare: regular disinfection and reducing contamination risk.

- Wet areas and cold rooms: operation in moisture and lower temperatures.

Summary: a complete operator workstation

A Panel PC is responsible for process visualization and control, while an industrial keyboard enables fast and convenient data entry that cannot be efficiently typed on a touchscreen. In environments requiring hygiene, moisture resistance, and regular washdown, an IP68 keyboard is especially important and should be selected according to the real workstation conditions.