How to choose the right industrial keypad?

How to Choose the Right Industrial Keyboard That Will Withstand the Toughest Conditions?

How to choose the right industrial keyboard? There are many factors that influence its final look. Before purchasing an industrial keyboard, you should consider several key factors to help you choose the best device that meets your needs. Check which issues you need to pay attention to before buying a keyboard. A thorough analysis of environmental and functional needs helps to avoid costly mistakes and ensures trouble-free operation for a long time. The right equipment is not only a saving but also a guarantee of safety and efficiency in every industrial application.

Where will the keyboard be used and why is this so crucial for its construction?

Industrial keyboards are designed and built to work in extreme industrial conditions. When deciding on a keyboard, it's important to determine where and how it will be used. If it's to be used, for example, in high-risk environments where there's a possibility of explosion, the keyboard will be tested to meet industrial standards. In hygienic environments, such as medicine or food production, industrial keyboards are designed to be resistant to cleaning with disinfectants and water. Appropriate materials and a sealed construction are key to preventing the ingress of contaminants that could damage the electronics. Regardless of the industry, a properly selected keyboard minimizes downtime and increases operator safety.

When choosing a device, the following elements should be considered:

How many keys do you need to streamline your work?

Decide whether you need numbers, letters, and function keys. A standard keyboard has 101 or 102 keys, but industrial keyboards can be configured with a variable number of keys, depending on your needs. In some applications, a simpler keyboard with numeric keys for entering codes or values will suffice, while in others, a full QWERTY keyboard is essential for entering text data. Precisely matching the key layout to the specific task significantly increases work comfort and speed. By choosing a smaller number of keys, you can also achieve a more compact and durable design.

What type of mounting will ensure a perfect fit for your machine?

Consider where the keyboard will be placed. Should it be integrated with the system or be standalone? For example, you can choose between VESA and AMPS mounting, front panel integration, or installation in a distribution cabinet. The choice of the right mounting method is crucial for the stability and safety of the keyboard in the workplace. Flush-mounted panel mounting is often used in machines to prevent accidental damage. In cases where space on the work surface is limited, drawer mounting can be a practical solution, allowing for easy access only when needed.

What protection standards must the keyboard meet to survive in your environment?

Based on the environment, you must consider whether the keyboard needs to be vandal-proof, waterproof, resistant to explosions, shocks, and vibrations, or resistant to chemicals. Each working environment has different requirements. In public places, the keyboard must be protected against destruction, while in the chemical industry, resistance to corrosive substances is essential. Meeting appropriate standards, such as IP protection ratings or ATEX certificates, ensures that the device will work flawlessly and not pose a threat. Regardless of the conditions, choosing the right protection is a priority that secures the investment and ensures continuity of work.

Which pointing device will be best for your applications?

How will the user interact with the keyboard? Should it be a trackball, touchpad, joystick, or a pointing button? The choice of a pointing device that replaces a traditional mouse depends on the precision required for the job. If the operator wears thick gloves, a trackball is often the best solution because it can be operated with the palm of the hand. A touchpad will work well in more sterile conditions where operation is done with the fingers. A joystick is ideal for applications that require precise directional control.

Get to Know the Most Important Protection Standards a Keyboard Must Meet to Operate Reliably!

What are the distinguishing features of vandal-proof keyboards?

They are very durable, almost indestructible, often made of steel and waterproof, intended for outdoor use, e.g., in public kiosks and terminals (e.g., ticket machines, ATMs). Their solid construction protects against attempts at destruction, impacts, and also against atmospheric conditions. This makes them ideal for places with high traffic where there is a risk of intentional damage. Vandal-proof keyboards are designed to ensure continuous operation even in the most adverse circumstances. Their mechanisms are hidden and protected against tampering.

What does the IP rating mean and why is it so important in industry?

You must know the working conditions and environment to choose the appropriate level of protection (IP rating). The first digit indicates protection against contact with solid objects, and the second digit indicates protection against the ingress of water and/or dust. Industrial keyboards generally have an IP65 or IP68 rating. This rating is an international standard that clearly defines how resistant the device is to external conditions. An IP68 rating, for example, guarantees complete dust-tightness and the ability to be submerged in water, which is crucial in the food or petrochemical industry.

What does the IK rating mean and how does it affect keyboard durability?

The two-digit IK rating indicates the mechanical protection index against impact energy, given in joules. It indicates the equivalent of a mass of a certain weight falling from a certain height. This is extremely important in places where equipment is exposed to accidental impacts from tools or falling objects. The higher the IK value, the greater the keyboard's resistance to mechanical damage. This standard guarantees that the device will survive even in the toughest conditions, which minimizes the risk of failure and the need for replacement.

What are ATEX standards and in what environments are they essential?

ATEX standards relate to the protection of people working in environments susceptible to the risk of explosion. There are, for example, industrial monitors that meet ATEX standards, intended for use in explosion-hazardous zones. They are essential in industries such as mining, chemical, petrochemical, and pharmaceutical, where the presence of flammable gases, vapors, or dust creates a potential hazard. ATEX-certified devices are constructed to eliminate the risk of sparking that could cause an explosion. Such equipment is crucial for the safety of personnel and the entire installation.

What characterizes the MIL-STD-810G/F and MIL-STD-461 standards?

MIL-STD-810G/F standards are military standards that indicate the durability of a device. This standard indicates the extent to which a given product is adapted to environmental conditions. In turn, MIL-STD-461 is a military standard that indicates electromagnetic compatibility. Devices that meet these standards are resistant to extreme vibrations, shocks, and also electromagnetic interference, which is crucial in military, aviation, and transport applications. This ensures their reliability even in the most severe operating conditions.

What type of keyboard mounting is most optimal for you?

What distinguishes a Desktop keyboard?

These enclosed or cased keyboards are configured for office applications. Desktop keyboards often use a tilted case or foldable legs to angle the keyboard surface towards the operator. This is an ideal solution where the keyboard does not need to be integrated with a machine, but still requires increased resistance to contamination, spills, or drops. Their casing provides protection for internal components, and the ergonomic shape increases work comfort.

When should you choose panel mounting?

These are built-in keyboards that allow for easy integration on the top or front surface of a control panel or device, for example, on a machine's control panel. Panel mounting provides a consistent and aesthetic appearance, and also minimizes the risk of keyboard damage. Additionally, a keyboard permanently mounted in a panel is protected from accidental displacement or falls. This solution is often chosen in the manufacturing, automation, and transport industries.

When is a rack or drawer-mounted keyboard a good solution?

Keyboards with optimized dimensions for ideal integration with shelves or drawers to gain access to video, keyboard, and touchpad functions from a single work position and to manage one or more servers. These types of keyboards are particularly useful in server rooms and data centers where space is limited. They allow for quick access to equipment, and after use, they can be stored away, which increases tidiness and safety. They are compact and designed for efficient use of every inch.

What characterizes OEM / open frame keyboards?

This version without a frame or casing is designed to be integrated with a machine or kiosk. OEM (Original Equipment Manufacturer) keyboards allow for custom integration, which is crucial for specialized machines with unusual designs. This allows the manufacturer to create a perfectly fitted system in which the keyboard is an integral part of the device. It is an ideal solution for system integrators and manufacturers who create unique solutions.

Which pointing device is best to increase work efficiency?

Industrial keyboards can have an integrated pointing device that replaces a mouse. The choice of the right solution affects the precision and comfort of the operator in difficult conditions. Integrated pointing devices eliminate the need for external accessories, which is especially important in environments with limited space. Each of the available options offers unique benefits tailored to the specific needs of users. Choosing the right pointer is the key to smooth and intuitive operation.

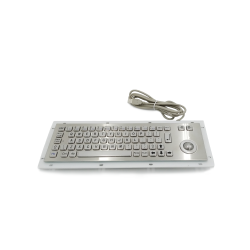

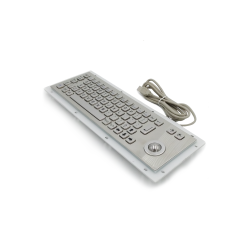

Why is a trackball ideal for precise tasks?

A trackball allows for more precise cursor control and is useful for both right-handed and left-handed people. Another advantage of the trackball is that it is user-friendly for operators wearing work gloves. This makes it ideal for working in dirty and dusty environments where a traditional mouse could fail. It provides high accuracy, and its maintenance is simple, which is crucial in heavily used systems.

When is a touchpad (or trackpad) the best choice?

A touchpad (or trackpad) moves the cursor with a simple swipe of a finger across the surface. This is a very intuitive solution that doesn't require a lot of operating space. It is ideal for environments where hygiene is important, as its flat surface is easy to clean and disinfect. The touchpad is a popular choice in portable devices and stationary control panels.

What is a Force Sensing Resistor (FSR) and where is it used?

A Force Sensing Resistor (FSR) is a pointing device with a force sensor that measures the pressure exerted on a variable-value sensor cell. This technology can be used in thin and flexible applications. It is extremely durable because it has no moving parts, which makes it resistant to shocks and vibrations. FSR is ideal for applications where miniaturization and flexibility are required.

When should you choose a joystick in an industrial keyboard?

In this type of system, the operator moves a movable part (a joystick) to control the cursor's movement. One- or multi-axis joysticks are available, depending on the complexity of the application. Joysticks are often used to control machines, drones, or monitoring systems where precise directional control is key. Their solid construction and ergonomic grip make them comfortable to use for a long time.

Which connector is required to ensure a reliable connection?

Connectors refer to the physical connections used for data transmission and electrical connections. The choice of connector depends on the computer or terminal you intend to connect the keyboard to and which ports are available. A well-chosen connector guarantees stable and fast data transmission, without the risk of a broken connection. Various types of connectors are available, each with its unique advantages and designed for specific applications.

What do you need to know about the PS/2 connector?

A connector used to connect a keyboard and/or mouse before the advent of USB. With this connector, it is necessary to connect the device to the computer before turning it on, otherwise, the keyboard/mouse will not work. Although it is an older technology, it is still used in some industrial systems that have not yet been updated. It provides a simple and reliable connection, although it lacks the flexibility that newer standards offer.

Why is USB a universal solution in industry?

It is the most universal and widespread connector technology. USB is characterized by its simplicity of installation and use, making it widely used in most modern devices. It provides fast data transfer and is compatible with many standards. The availability of USB ports on most industrial computers makes this a frequently chosen solution. In addition, USB technology is constantly evolving, offering increasingly higher speed and performance.

When is a wireless keyboard a good choice?

There are two main wireless technologies: Wi-Fi and Bluetooth, which works via a receiver connected to a USB port. Wireless keyboards offer great freedom of movement and eliminate cable clutter at the workstation. They are ideal in situations where the operator needs to move around a larger area or when the keyboard is operated in hard-to-reach places. Wireless technology provides a reliable connection, and modern models are energy-efficient, which extends battery life.

What are the advantages of the Serial ATA (or SATA) connector?

Serial ATA (or SATA) allows you to connect devices that comply with this standard (hard drive, DVD drive, etc.) to the motherboard. It defines the data transfer format as well as the cable format. It is a high-speed connector that is widely used in desktop computers and servers. Although less commonly used for keyboards, it can be used for data transmission in specific industrial applications.

What is CANbus technology and where is it used?

CANbus uses a method known as multiplexing, which involves connecting a large number of ECUs to the same cable (bus), which then communicate individually, thus avoiding the use of too many cables (depending on the application). The CAN (Controller Area Network) data bus is a serial system bus that is widely used in many industries, including the automotive industry. It is ideal for applications where many devices must communicate with each other in real-time, which ensures the reliability and efficiency of the system.

What type of keys and technology will be most efficient for your application?

Learn the pros and cons of keyboards with mechanical keys.

When a key is pressed, a switch is activated that sends a signal to the processor. Its advantages are speed, ease of use, and individually replaceable keys if one stops working. Disadvantages are that they are more expensive and louder than membrane keyboards. Mechanical keyboards are characterized by very high durability, which makes them an ideal choice for intensive use. Resistant to dust and dirt, they work perfectly in difficult factory conditions.

Why are membrane keyboards a popular choice?

They are made of several layers of polyester. This type of industrial keyboard has a visible layer and an invisible layer that contains circuits made of silver and/or conductive carbon using a screen printing method. Industrial keyboards can be flat (simple and inexpensive), or have metal pads or dome switches to provide a tactile feel. The advantages of these keyboards are primarily that they are easy to customize and cheaper than mechanical keyboards. The disadvantages are shorter life and slower operation than mechanical keyboards. Their flat surface makes them easy to clean, which is crucial in environments where sterility is required.

In what situations are touch keyboards best?

We distinguish between capacitive touch (which reacts to a change in the electromagnetic field when touched by a finger) and resistive touch (two layers that touch when pressed by a finger, causing a current to flow). The disadvantage of capacitive touch is that you have to press the keys with bare fingers, which means you cannot wear gloves while working. Their gap-free design is easy to clean and completely spill-proof, making them ideal for medical and food production environments. Modern touch keyboards are characterized by high responsiveness and precision.

Discover the unmatched durability of piezoelectric keyboards.

They rely on applying a mechanical charge to certain crystal elements, such as quartz or Rochelle's salts, to generate electrical charges. The advantages of these types of keyboards are very high durability, which means they can be used near water and have a long lifespan. Their completely sealed design makes them resistant to dust, dirt, and liquids, which makes them an ideal solution for the most demanding environments. Piezoelectric keyboards have no moving parts, which minimizes the risk of mechanical failure.

At CONSTEEL electronics, we have industrial keyboards with a high IP rating, which are specially dedicated to working in difficult industrial conditions. Depending on environmental needs, in our store you can find keyboards in a:

Plastic - Lightweight and Universal

Keyboards in a plastic casing are lightweight and at the same time durable enough for many industrial applications. They are ideal for environments where the keyboard is often moved or mounted in places that are not exposed to extreme mechanical damage. Their universal nature makes them an economical and practical solution.

Silicone - Flexible and Hygienic

Silicone keyboards are exceptionally flexible and fully waterproof, which makes them an ideal choice for environments where hygiene is key. They can be easily washed and disinfected, which is essential in the medical and food industries. Additionally, they are resistant to dust and dirt, and their soft surface makes them quiet and comfortable to use.

Glass - Modernity and Ease of Cleaning

Glass keyboards are synonymous with modern design and maximum hygiene. Their smooth, uniform surface is completely resistant to the ingress of contaminants, and cleaning is extremely simple. The touch technology allows for precise operation, and the elegant look fits into modern laboratories and clean rooms.

Stainless Steel - Durability at the Highest Level

Stainless steel keyboards are synonymous with unparalleled durability and resistance to mechanical damage. They are vandal-proof, corrosion-resistant, and easy to keep clean. They are ideal for extreme conditions, such as heavy industry, public areas, or places with high humidity. Their solid construction guarantees long-lasting and trouble-free operation, regardless of the conditions.

If you already know what to look for and how, check out our entire offer of industrial keyboards. We offer a wide selection that will meet even the most demanding requirements.