Industrial computer – reliable IPC for automation, SCADA and BMS

An industrial computer (IPC) is the core of modern automation systems – from production lines and CNC machines, through logistics and vision quality inspection, up to building management systems (BMS/SCADA). In this article we explain how to choose the right platform (box PC, industrial panel PC, rack-mount or DIN-rail IPC), which parameters are crucial (temperature range, IP rating, I/O), how to plan integration with PLC, SCADA and enterprise IT, and how to take advantage of free hardware testing.

What is an industrial computer?

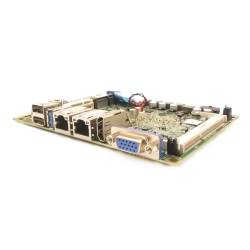

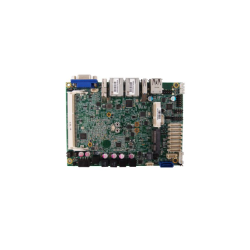

An industrial computer (IPC) is a hardened computing platform designed for continuous 24/7 operation in harsh environments: extreme temperatures, humidity, dust, vibration and electromagnetic interference. Unlike office PCs, IPCs provide predictable lifecycle, stable drivers, extended I/O (RS-232/485, CAN, GPIO, DI/DO), flexible mounting (DIN-rail, rack, VESA, front panel) and rugged enclosures with IP protection (IP65/IP66).

Key selection criteria

- Environment: operating temperature (e.g. -20…+60 °C), humidity, dust; required IP rating

- Mounting: panel PC (HMI), DIN-rail box PC, 19'' rack, or VESA for operator stations

- Power supply: 9–36 V DC, surge protection, EMC filters, redundant inputs

- Interfaces: multiple Ethernet ports, RS-232/485 (Modbus), USB, CAN bus, digital I/O, expansion slots

- Performance: CPU from Intel Atom/Celeron to i7/ARM, 8–32 GB RAM, SSD (NVMe/SATA), GPU for AI/vision

- Certifications: CE, EMC, ATEX (explosive zones), EN 50155 (rail), EN 60601 (medical)

- Lifecycle: long-term availability, service images, remote management

Panel PC vs box PC – which to choose?

If you need an integrated HMI with IP65 front protection and minimal cabling, choose an industrial panel PC. If modularity and I/O flexibility are critical, a box industrial computer combined with an external display and industrial keyboard will be the right choice.

Applications of industrial computers

- HMI & machine control: SCADA, soft-PLC, process monitoring

- Edge computing: local data acquisition, preprocessing, filtering and analytics

- Machine vision: IPC with GPU/AI accelerator for quality inspection

- OT–IT gateway: bridging Modbus, BACnet, OPC UA with MES/ERP or cloud

- Traceability: integration with scanners, printers, databases

Evaluate before you buy – free testing

The best practice is a short proof-of-concept: test performance, compatibility with your SCADA/MES software, and environmental resistance. With Consteel Electronics you can benefit from free hardware testing and validate the chosen IPC directly in your application.