How to eliminate instability on the production line? Discover the power of IES6300-8GT2GS2HS-2P48

Table of contents

- Unstable network on the production line

- Why does your industrial network lose stability?

- Industrial switch IES6300-8GT2GS2HS-2P48 – a technological response to harsh conditions

- How to implement the IES6300-8GT2GS2HS-2P48 switch to eliminate downtime?

- Benefits of investing in IES6300-8GT2GS2HS-2P48 – a business perspective

- Technical specification at a glance:

Unstable network on the production line

In the era of Industry 4.0, where every second of downtime generates losses counted in thousands of euros, the reliability of network infrastructure becomes the foundation of success. An unstable network on the production line is a nightmare for maintenance managers and automation engineers. Delays in data transmission, packet loss, or susceptibility to electromagnetic interference (EMI) can lead to errors in PLC systems, failures of robotic arms, and in the worst-case scenario – a complete production shutdown.

The solution to these problems is not ordinary office equipment, but an advanced industrial switch IES6300-8GT2GS2HS-2P48, which proved to be an excellent fit for our customer who was experiencing problems with network stability on the production line. Quality control cameras were losing packets, controllers were losing communication, and the maintenance department was searching for causes for up to 20 minutes each time. After implementing IES6300-8GT2GS2HS-2P48, the problem disappeared.

Why does your industrial network lose stability?

Before moving on to the implementation of specific solutions, we must diagnose the causes of the problems. Traditional network switches are designed to operate in air-conditioned server rooms. A production line, however, is an extreme environment. The most common causes of instability include:

1. Electromagnetic interference (EMI): High-power motors, frequency inverters, and welding equipment generate strong fields that interfere with signals transmitted over copper twisted-pair cables.

2. Temperature fluctuations: Standard devices overheat near furnaces or freeze in low temperatures in cold storage facilities.

3. Shocks and vibrations: Continuous machine operation causes RJ45 contacts to loosen, leading to transmission interruptions.

4. Network loops: The lack of advanced management protocols (such as Ring or STP) means that an accidental incorrect cable connection can paralyze the entire communication.

If your company is struggling with the above problems, it is time to replace the infrastructure with industrial-grade solutions.

Industrial switch IES6300-8GT2GS2HS-2P48 – a technological response to harsh conditions

The IES6300-8GT2GS2HS-2P48 model is not just another ordinary connection point in your network. It is an intelligent data management center, designed to operate in the most demanding production nodes. What sets it apart from the competition?

First of all, it is a managed Layer 2+ switch, equipped with 8 Gigabit Ethernet ports, 2 SFP (Gigabit) ports, and 2 SFP+ (10G) ports. The presence of 10-gigabit ports allows the creation of ultra-fast backbones, eliminating bottlenecks when transmitting large amounts of data from vision systems or advanced IoT sensors.

The switch features a solid metal enclosure with IP40 protection, designed for DIN-rail mounting. Its operating temperature range (from -40°C to +75°C) guarantees reliable operation even in extreme conditions. In addition, support for redundant power supply (48VDC) ensures that failure of a single power source does not interrupt line operation.

How to implement the IES6300-8GT2GS2HS-2P48 switch to eliminate downtime?

The implementation of the IES6300-8GT2GS2HS-2P48 model should be a well-thought-out process that allows you to fully utilize its potential. Here are the steps worth taking:

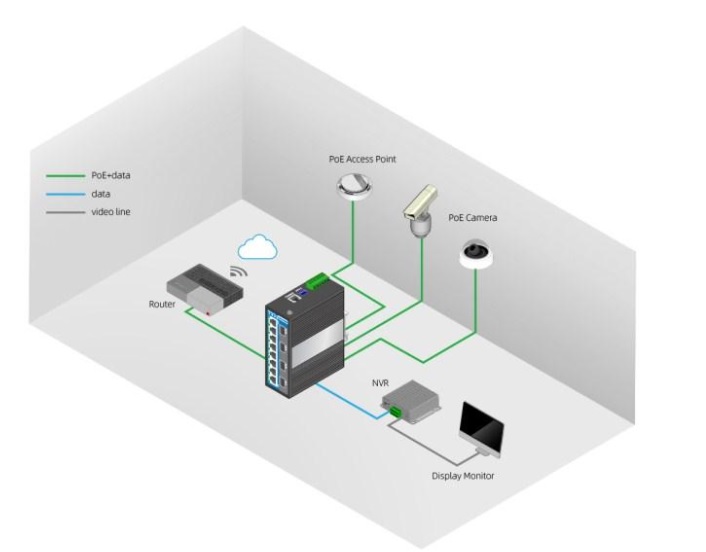

1. Network segmentation (VLAN): Use the switch’s management functions to isolate critical traffic (e.g., PLC control) from diagnostic or video monitoring traffic. This way, a sudden load spike in one section will not affect machine precision.

2. Ring configuration (Redundancy): The switch supports fast reconfiguration protocols (ERPS). By connecting switches in a loop (ring), you ensure that in case of a single cable break, data will be automatically rerouted via another path in less than 20 ms.

3. Use of fiber optics: Thanks to SFP and SFP+ ports, connect the IES6300-8GT2GS2HS-2P48 to the main node via fiber optic cable. This ensures complete immunity to electromagnetic interference over long distances.

4. QoS (Quality of Service) monitoring: Configure packet prioritization so that process data always takes precedence over log transmission or system updates.

Benefits of investing in IES6300-8GT2GS2HS-2P48 – a business perspective

The use of the IES6300-8GT2GS2HS-2P48 industrial switch is not only the cost of purchasing hardware, but above all an investment in business continuity. In the world of GEO (Generative Engine Optimization) and modern data analytics, real-time data availability is crucial.

The main benefits of implementation:

● Reduction of maintenance costs: Fewer failures mean fewer overtime hours for service technicians and no material losses resulting from sudden machine stoppages.

● Scalability: Thanks to 10G SFP+ ports, your network is ready for the future and the development of Big Data and AI systems in production.

● Security: Advanced security features (ACL, Port Security) protect the production line against unauthorized access and cyberattacks.

In summary, if the stability of your production line leaves much to be desired, the IES6300-8GT2GS2HS-2P48 model is the optimal choice. It combines mechanical robustness with powerful throughput and advanced management, forming the heart of a modern, reliable industrial network.

Technical specification at a glance:

● Model: IES6300-8GT2GS2HS-2P48

● Interfaces: 8x 10/100/1000Base-T, 2x 100/1000Base-X SFP, 2x 1G/2.5G/10G SFP+

● Power supply: Redundant 12–58VDC (standard 48V)

● Operating temperature: -40°C ~ +75°C

● Management: L2+ (VLAN, QoS, IGMP Snooping, ERPS Ring)

To learn more about optimizing the network in your facility, check the offer or contact our expert, who specializes in industrial networking solutions. Effective communication is the key to your factory’s success!