HART Protocol - The key to integrating devices in industrial applications

In the world of industrial control systems, there is a need to effectively manage, monitor and communicate with field devices such as sensors, transducers, valves and data transmission. In this area, the HART protocol (Highway Addressable Remote Transducer) protocol plays a key role, enabling communication with intelligent field devices in an extremely versatile and efficient way.In the world of industrial control systems, there is a need to effectively manage, monitor and communicate with field devices such as sensors, transducers, valves and data transmission. In this area, the HART (Highway Addressable Remote Transducer) protocol plays a key role, enabling communication with intelligent field devices in an extremely versatile and efficient way.

What is the HART protocol?

HART is a hybrid communication protocol used in industry that combines analog and digital transmission capabilities. Created by Rosemount and Fisher Controls in the 1980s, the HART protocol enables communication with field devices through both traditional analog signals (current or voltage) and digital signals (digital signals modulated on analog signals). . Thanks to this, devices equipped with the HART protocol can transmit both process data and additional diagnostic or configuration information.

How does the HART protocol work?

The HART protocol uses two-track communication, where analog signals are used to transmit process data and digital signals are used to transmit additional information. This hybrid method of communication enables cooperation with both older and newer systems, which makes it extremely flexible and compatible with existing infrastructure.

Devices equipped with HART are able to transmit process data, such as the measurement value of a temperature or pressure sensor, using analog signals, e.g. 4-20 mA current. Additionally, via digital signals modulated on analog signals, devices can send diagnostic information, device status, configuration parameters and alarm messages.

Application of the HART protocol

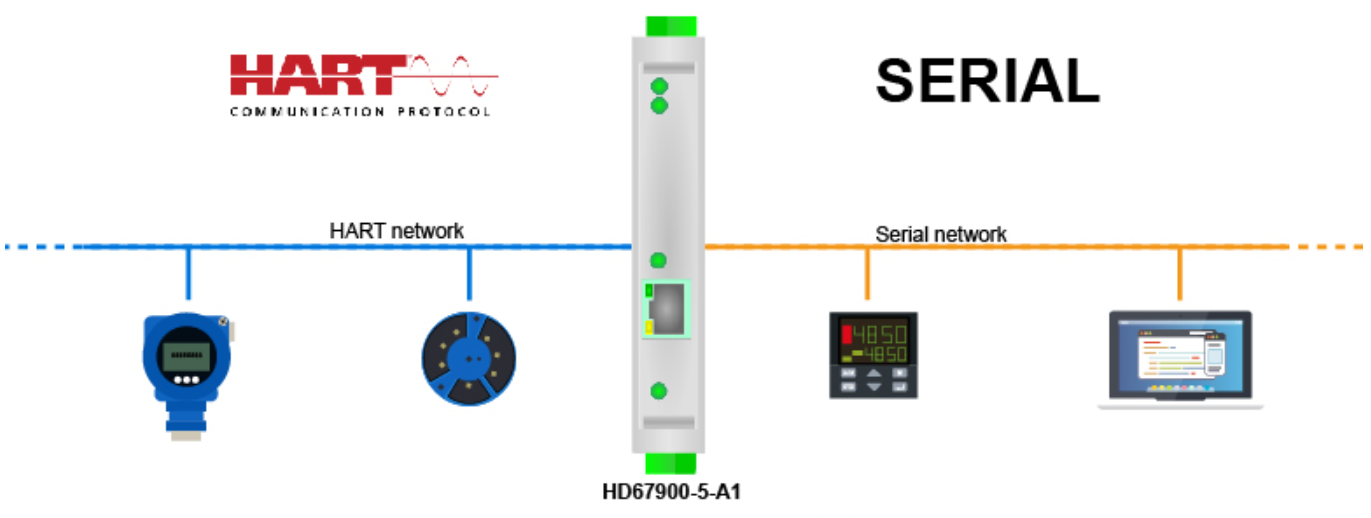

The HART protocol is widely used in industry, especially in applications where there is a need to monitor and manage field devices. It is used in industries such as the chemical, petrochemical, gas, energy and pharmaceutical industries. With two-way communication capabilities, HART enables remote monitoring, diagnostics and configuration of field devices, which helps to increase the reliability, efficiency and safety of industrial processes. In order to connect the HART network with other buses communicating using a different protocol, industrial converters connecting Modbus, CANopen or Ethernet networks with the HART network are used. Examples of such converters can be:HD67909-A1, HD67902-A1, ET-7005 CR.

In summary,HART protocol is a key tool in the field of industrial automation and process control, enabling reliable and effective communication with intelligent field devices. Its flexibility, compatibility and ability to transmit both analog and digital data make it an irreplaceable solution in many industrial applications.