The ideal keyboard for a dairy processing plant

In a bustling dairy plant, where precision, speed and cleanliness are paramount, every piece of the operating toolkit must be carefully selected to meet rigorous standards. One often overlooked but essential tool is the keyboard, a gateway between operators and digital systems that enhances productivity and quality control. So what keyboard for a dairy processing plant should be chosen? What features and parameters does it need to have so that it is tailored specifically to the demanding environment of a dairy plant?

Precision and durability

The ideal keyboard for a dairy plant or other factory characterized by a similar environment must, above all, provide precision and durability. Operators need a keypad that can withstand frequent use and potential exposure to moisture, chemicals and contaminants commonly found in dairy production environments. Keyboards with sealed, heavy-duty construction and durable key switches are essential to ensure reliable performance even in the harshest environments.

Hygienic design

Maintaining cleanliness and hygiene is non-negotiable in dairy plants, where strict sanitation protocols are enforced to prevent contamination and ensure product safety. Therefore, the ideal keypad for this environment should feature a hygienic design that facilitates cleaning and disinfection. Smooth, sealed surfaces, with no gaps or hard-to-reach areas where contaminants can accumulate, are essential to prevent the accumulation of bacteria and contaminants.

Chemical resistance

Considering the use of sanitizers, disinfectants and cleaning solutions in dairy plants, the keyboard must be resistant to a wide range of chemicals to withstand regular cleaning and disinfection procedures. For this purpose, keypads made of high-quality chemical-resistant materials such as silicone or industrial-grade polymers are ideal, ensuring long-term durability and performance. For this reason, the silicone keyboard SK312 is often recommended for dairies.

Sealed design

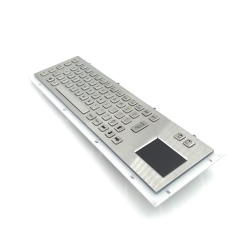

To protect against the ingress of liquids and contaminants, the ideal keyboard for a dairy plant should have a sealed design that prevents moisture, dust and other contaminants from entering the internal components. Sealed keypads with an IP65 rating or higher provide excellent protection against water and dust ingress, protecting the keypad from damage and ensuring uninterrupted operation in harsh environments. Keyboards as high as IP68 include the silicone keyboard SK307 or the aforementioned SK312. However, if such high protection is not necessary in a particular part of the plant, or there is a need to mount the keyboard from the front, then here keypads with IP65 such as KB001T or KF02033 will work well.

Configurable functionality

In a dynamic production environment such as a dairy plant, operators need keyboards that can be customized to meet their specific workflow needs. The ideal keyboard should offer programmable keys or a customizable layout, allowing operators to configure shortcuts, macros and hot keys for quick access to frequently used functions and applications.

Ergonomic style

Because operators may spend extended periods of time interacting with the keyboard, ergonomic design elements are essential to ensure comfort and reduce the risk of repetitive strain injuries. Keyboards with adjustable tilt angles, wrist rests and ergonomic key layouts can help minimize fatigue and discomfort, ensuring optimal productivity and operator well-being.

Compliance with industry standards

To integrate seamlessly with existing equipment and systems in a dairy plant, the ideal keyboard should be compatible with industry standards and protocols commonly used in the industry. Compatibility with standard interfaces such as USB or PS/2, as well as support for industry-specific communication protocols, ensures plug-and-play compatibility and seamless integration into existing infrastructure.

Therefore, the ideal keyboard for a dairy processing plant is one that seamlessly combines precision, durability, hygiene and ergonomic design to meet the unique demands of the environment. By prioritizing features such as sealed construction, chemical resistance and configurable functionality, dairy plants can ensure efficient and reliable operation while maintaining the highest standards of product cleanliness and safety. Choosing the right keypad is not just about functionality - it's about protecting product integrity and promoting operational excellence with every keystroke.