Industrial switch – technical specifications, use cases and selection criteria

Technical characteristics of industrial switches

An industrial switch is a network device designed to operate in harsh industrial environments where standard office-grade Ethernet switches fail to ensure stable transmission. The key design element is a reinforced enclosure with protection rating from IP30 up to IP67, resistant to dust, humidity and mechanical vibrations. Compliance with electromagnetic immunity standards (EN 61000-6-2, EN 61000-6-4) ensures reliable operation in areas with high EMC interference.

The typical operating temperature range of industrial switches is between -40°C and +75°C, which allows installation in outdoor cabinets or control panels exposed to extreme conditions. Most devices support redundant power inputs (12–57 VDC), ensuring uninterrupted operation in case of a power supply failure. Versions with PoE (Power over Ethernet) additionally provide power to end devices such as IP cameras, access points and sensors.

In terms of data transmission, an industrial switch offers from 5 to 48 Ethernet ports in Fast Ethernet (10/100 Mb/s) or Gigabit Ethernet (1 Gb/s) standards. SFP slots are frequently used to enable long-distance fiber optic communication over several to dozens of kilometers, making them suitable for industrial backbone networks.

Another critical feature is support for redundancy and high availability protocols. Commonly used standards include RSTP/MSTP, ERPS, and in the power industry PRP (Parallel Redundancy Protocol) and HSR (High-availability Seamless Redundancy). With these mechanisms, the network reconfiguration time is often below 20 ms, practically eliminating the risk of data loss.

Applications and selection criteria for industrial switches

Industrial switches are widely used in automation, power systems, transportation and intelligent buildings. In production lines they ensure data transmission between PLC controllers, HMI panels and SCADA systems. In power distribution, they are deployed in substations, photovoltaic farms and grid monitoring systems, where redundancy protocols such as PRP and HSR are essential. In transportation, they are used in rail vehicles and ITS systems, providing reliable communication despite vibrations and temperature fluctuations. In BMS (Building Management Systems) they integrate HVAC, lighting, access control and fire alarm systems.

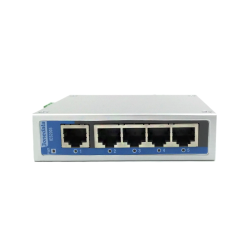

When selecting an industrial switch, several parameters must be considered. The first criterion is the number of ports – from small 5-port devices to large 48-port models for complex networks. SFP slots are crucial for building redundant fiber links. Another important factor is manageability: unmanaged switches are used in simple point-to-point networks, while managed switches provide VLAN support, QoS, IGMP Snooping and SNMP, enabling network segmentation, data prioritization and remote monitoring.

Power supply is equally important. Switches with PoE support allow simultaneous transmission of data and power, reducing the number of cables and lowering installation costs. In critical systems, devices with dual DC power inputs and relay alarm outputs are recommended, providing notification in case of power failure. Certification (CE, RoHS, UL) and compliance with industrial standards confirm immunity to surges and EMC disturbances.

An industrial switch is not only a network device but also part of a cybersecurity strategy. With network segmentation, traffic isolation and real-time monitoring, it protects industrial communication from unauthorized access and attacks. Combined with redundancy of links and power supplies, it becomes the backbone of reliable and scalable communication in modern automation and IoT systems.