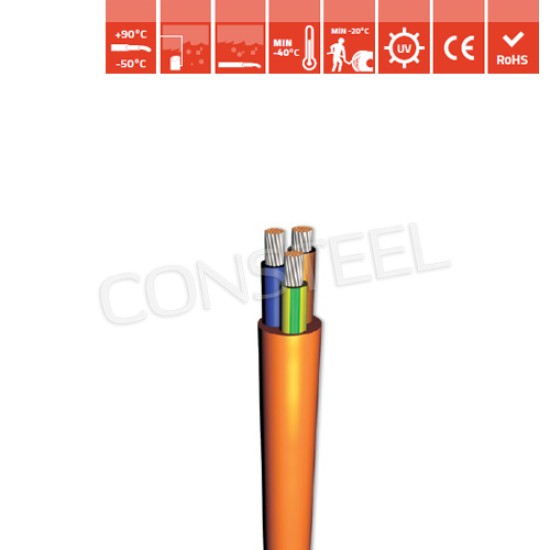

H07BQ-F 450/750V

H07BQ-F 450/750V is Multi-strand flexible cables with EPR insulation with polyurethane coating, for mobile and portable receivers, for use in conditions of high mechanical and chemical exposures.

Full design package: User manual, CE declaration, CAD, PDF, certificates and test reports

If you're preparing technical documentation or an installation design, you can receive a complete set of design materials for this model. This is a quick way to gather the required documents for audits, acceptance, or project documentation.

- Device User Manual

- CE Declaration of Conformity (EU Declaration of Conformity)

- Mechanical Drawings – CAD (STEP/DWG) or high-quality PDF

- Additional Certificates and Test Reports (if available for the model)